Description

TYGK Encoding system

|

①Production Category |

②TYGK Grade |

③Type Classfication |

④Shape Code |

⑤Diameter |

⑥Lengh |

|

H0-Unground |

25U-TY25UF |

BR-Rods |

1-No Chamfer |

|

|

|

H1-Half-ground |

25S-TY25S |

BQ-Ball-Nose Endmill Blank |

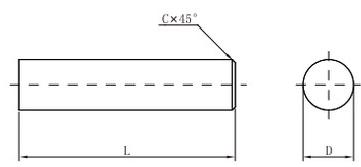

2-Chamfer |

|

|

|

H2-Ground H6 |

20-TY20 |

Bt Step-Rods |

3-Double Chamfer |

|

|

|

H7-Ground H7 |

05A-TY05A |

|

|

|

|

|

|

10U-TY10UF |

|

|

|

|

Grade Introduction

|

Grade |

ISO Application Grade |

GraSiz(µm) |

Cobal Content (%) |

Hardnes (HRA) |

Density (g/cm³)

|

TRS (N/m²) |

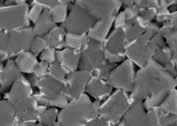

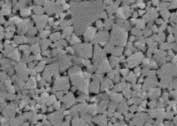

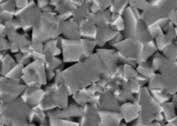

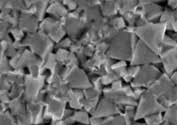

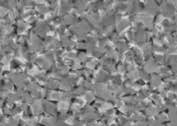

Microstructure 10000x |

|

TY05A |

K15 |

1.0 |

6.0 |

92.5 |

14.95 |

2450 |

|

|

TY10UF |

K05-K10 |

0.4 |

6.0 |

94.0 |

14.80 |

3800 |

|

|

TY20 |

K20-K40 |

0.6 |

10.0 |

91.8 |

14.45 |

3800 |

|

|

TY25S |

K20-K40 |

0.5 |

11.0 |

92.4 |

14.25 |

4000 |

|

|

TY25UF |

K20-K40 |

0.4 |

12.0 |

92.5 |

14.10 |

4200 |

|

|

|

TY10UF |

TY25S |

TY25UF |

TY20 |

TY05A |

|

|

Type ofCutting Tools |

Recommended Grade(Suitable:△) |

|||||

|

Endmill |

|

△ |

△ |

△ |

△ |

|

|

Drills |

△ |

△ |

△ |

△ |

△ |

|

|

Reamer |

|

△ |

△ |

△ |

|

|

|

Work Material |

Recommended Grade(◎:Best;Ο:Suitable) |

|||||

|

|

Non Alloy Steel |

Ο |

◎ |

◎ |

◎ |

|

|

P |

Low Alloy Steel |

|

Ο |

Ο |

|

◎ |

|

|

High Alloy Steel |

|

◎ |

◎ |

◎ |

|

|

M |

Stainless Steel |

Ο |

|

◎ |

|

|

|

|

Grey Cast Iron |

Ο |

◎ |

Ο |

◎ |

◎ |

|

K |

Ductile Cast Iron |

|

|

Ο |

◎ |

|

|

|

Spheroidal Graphite Iron |

◎ |

◎ |

Ο |

Ο |

Ο |

|

N |

Aluminum Alloy |

|

Ο |

Ο |

◎ |

Ο |

|

CopperAlloy |

|

◎ |

◎ |

◎ |

Ο |

|

|

S |

Nickel Alloy |

|

|

◎ |

◎ |

◎ |

|

Titanium Alloy |

|

◎ |

◎ |

◎ |

◎ |

|

|

H |

Hardened Steel |

|

|

◎ |

Ο |

◎ |

|

Others |

Wood |

|

Ο |

Ο |

Ο |

Ο |

|

Fiber Glass Reinforced Plastics |

|

◎ |

◎ |

|

◎ |

|

|

Composite |

|

◎ |

◎ |

Ο |

Ο |

|

TY25S:Endmil、reamers and gravers are recommended.Excllent performance for high speed cuting. Suitable for cutting hardened steel,aluminum alloy and Titanium alloy.

TY20:Drill and endminlls are recommended.Suitable for cuting die steel、grey cast iron、austenitic stainles steel and heat resistant alloy.

TY05A:Drill、endmil and burr are recommended.Suitable for cuting non-ferous metal,aluminum,copper and graphite(coating in needed)

This grade recommendation is for your reference only, due to the shape of cutting tools and coating both have great influence on cutting tool's performance. Please go to specialty of grade for further information to assist your grade choice.

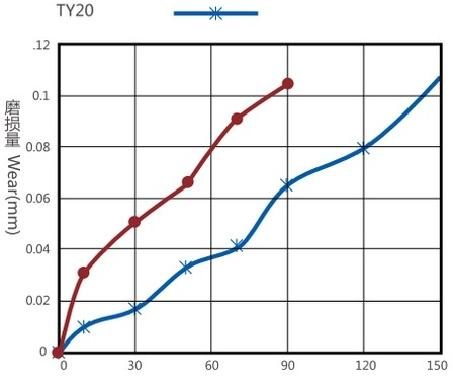

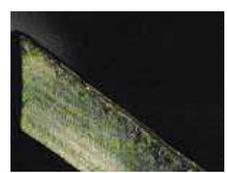

TY20 Case

Milling Die Steel(40HRC)

|

|

Work Piece Material |

Tool Type |

Grade |

||

|

Working Conditions |

Die Steel Skd61(40hrc) |

Endmill |

TY20 |

||

|

Mill Dia. (mm) |

Flute Length(mm) |

Number of Flutes(n) |

Coating |

Cooling |

|

|

8 |

20 |

4 |

AlCrN |

Water Soluble |

|

Cutting Conditions:

VC=95m/min

fz=840mm/min ae=0.8mm

ap=8mm

LIFE +60%

Cutting Length(m)

Competitor O company

Competitor O company TY20

TY20

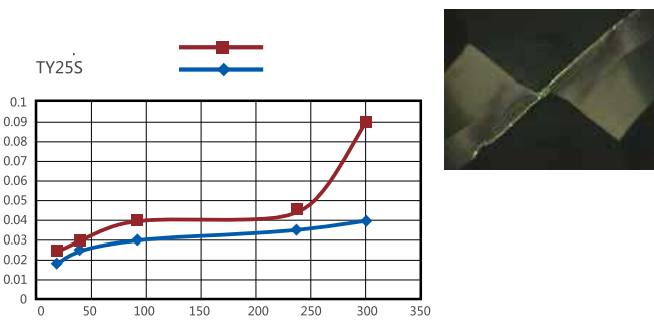

TY25S Case

Milling Die Steel(55HRC)

|

|

Work Piece Material |

Tool Type |

Grade |

||

|

Working Conditions |

Die Steel SKD61(55HRC) |

Endmill |

TY25S |

||

|

Mill Dia. (mm) |

Flute Length(mm) |

Number of Flutes(n) |

Coating |

Cooling |

|

|

6 |

- |

2 |

TiAIN |

Mist Oil |

|

Cutting Conditions:

VC=254m/min

fz=4200mm/min ae=0.2mm

ap=2mm

LIFE +60%

Cutting Length(m) Competitor M company

TY25S

Ground Rods with Chamfer

Ground Rods with Chamfer -Inch

|

TYGKProduction Category H2/H7 ISO h6/h5 |

||||

|

Specification |

Dimension |

Tol.of OD |

||

|

OD |

L |

h6 |

h5 |

|

|

BR2031038 |

1/8 |

1/2 |

√ |

√ |

|

BR2031050 |

1/8 |

2 |

√ |

√ |

|

BR2031063 |

1/8 |

2-1/2 |

√ |

√ |

|

BR2031076 |

1/8 |

3 |

√ |

√ |

|

BR2047050 |

3/16 |

2 |

√ |

√ |

|

BR2047076 |

3/16 |

3 |

√ |

√ |

|

BR2063050 |

1/4 |

2 |

√ |

√ |

|

BR2063063 |

1/4 |

2-1/2 |

√ |

√ |

|

BR2063076 |

1/4 |

3 |

√ |

√ |

|

BR2063101 |

1/4 |

4 |

√ |

√ |

|

BR2079063 |

5/16 |

2-1/2 |

√ |

√ |

|

BR2050100 |

5.0 |

100 |

√ |

√ |

|

BR2050150 |

5.0 |

150 |

√ |

√ |

|

BR2060050 |

6.0 |

50 |

√ |

√ |

|

BR2060060 |

6.0 |

60 |

√ |

√ |

|

BR2060075 |

6.0 |

75 |

√ |

√ |

|

BR2060100 |

6.0 |

100 |

√ |

√ |

|

BR2060150 |

6.0 |

150 |

√ |

√ |

|

BR2070055 |

7.0 |

55 |

√ |

√ |

|

BR2070060 |

7.0 |

60 |

√ |

√ |

|

BR2080060 |

8.0 |

60 |

√ |

√ |

|

BR2080075 |

8.0 |

75 |

√ |

√ |

|

BR2080080 |

8.0 |

80 |

√ |

√ |

|

BR2080090 |

8.0 |

90 |

√ |

√ |

|

BR2080100 |

8.0 |

100 |

√ |

√ |

|

BR2080150 |

8.0 |

150 |

√ |

√ |

|

BR2100070 |

10.0 |

70 |

√ |

√ |

|

BR2100075 |

10.0 |

75 |

√ |

√ |

|

BR2100090 |

10.0 |

90 |

√ |

√ |

|

BR2100100 |

10.0 |

100 |

√ |

√ |

|

BR2100125 |

10.0 |

125 |

√ |

√ |

|

BR2120110 |

11.0 |

110 |

√ |

√ |

|

BR2120075 |

12.0 |

75 |

√ |

√ |

|

BR2120090 |

12.0 |

90 |

√ |

√ |

|

BR2120100 |

12.0 |

100 |

√ |

√ |

|

BR2120120 |

12.0 |

120 |

√ |

√ |

|

BR2140075 |

14.0 |

75 |

√ |

√ |

|

BR2140110 |

14.0 |

110 |

√ |

√ |

|

BR2140125 |

14.0 |

125 |

√ |

√ |

|

BR2160100 |

16.0 |

100 |

√ |

√ |

|

BR2160125 |

16.0 |

125 |

√ |

√ |

|

BR2180100 |

18.0 |

100 |

√ |

√ |

|

BR2180150 |

18.0 |

150 |

√ |

√ |

|

BR2200100 |

20.0 |

100 |

√ |

√ |

|

BR2200120 |

20.0 |

120 |

√ |

√ |

|

BR2200150 |

20.0 |

150 |

√ |

√ |

|

BR2250100 |

25.0 |

100 |

√ |

√ |

|

BR2250150 |

25.0 |

150 |

√ |

√ |

|

|

|

|

|

|

|

|

Diameter D,inch |

Chamfer C,inch |

||

|

(Range) |

(Tol.) |

(Range) |

(Tol.) |

|

|

1/8≤0Ds1 |

h5,h6 |

1/8s0D<7/16 |

+.015±.004 |

|

|

|

|

7/16sODs1 |

+.031±.008 |

|

|

Length L,inch |

Angle,Degrees |

|||

|

(Range) |

(Tol.) |

(Range) |

(Tol.) |

|

|

1/2≤Ls3/4 |

+1/16,-0 |

1/8sOD≤1 |

45°±3° |

|

(1)BR2 Thecode for series with chamfer is BR2

(2)BR1 The code forseries without chamfer is BR1

(3)BR3 The code for series withtwo chamfers is BR3

unit(inch)

Ordering Example:

(The type is for orderingexample,whose bottom is orange.)

|

Ordering Table |

||||||

|

NO. |

Grade |

Ordering Type |

Production Category &Type |

Tol. |

Amounts |

Remark |

|

1 |

TY20 |

H2-BR2031038 |

TYGK |

5000 |

|

|

|

2 |

|

|

|

|

|

|

Note:It will be taken as TYGK standard,if no tolerance isoffered.

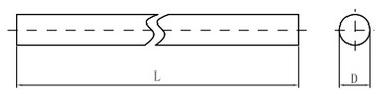

Unground Rods

Unground Rods -Inch

|

TYGK Production Category HO:Blanks |

||

|

Specification |

Dimension |

|

|

OD |

L |

|

|

BR1031333 |

1/8 |

13-1/8 |

|

BR1035333 |

9/64 |

13-1/8 |

|

BR1039333 |

5/32 |

13-1/8 |

|

BR1043333 |

11/64 |

13-1/8 |

|

BR1047333 |

3/16 |

13-1/8 |

|

BR1051333 |

13/64 |

13-1/8 |

|

BR1055333 |

7/32 |

13-1/8 |

|

BR1059333 |

15/64 |

13-1/8 |

|

BR1063333 |

1/4 |

13-1/8 |

|

BR1071307 |

9/32 |

12-1/8 |

|

BR1075307 |

19/64 |

12-1/8 |

|

BR1079307 |

5/16 |

12-1/8 |

|

BR1083307 |

21/64 |

12-1/8 |

|

BR1087307 |

11/32 |

12-1/8 |

|

BR1091307 |

23/64 |

12-1/8 |

|

BR1095307 |

3/8 |

12-1/8 |

|

BR1099307 |

25/64 |

12-1/8 |

|

BR1103307 |

13/32 |

12-1/8 |

|

BR1107307 |

27/64 |

12-1/8 |

|

BR1111307 |

7/16 |

12-1/8 |

|

BR1115307 |

29/64 |

12-1/8 |

|

BR1119307 |

15/32 |

12-1/8 |

|

BR1123307 |

31/64 |

12-1/8 |

|

BR1127307 |

1/2 |

12-1/8 |

|

BR1134307 |

17/32 |

12-1/8 |

|

BR1142307 |

9/16 |

12-1/8 |

|

BR1158307 |

5/8 |

12-1/8 |

|

BR1174307 |

11/16 |

12-1/8 |

|

BR1190307 |

3/4 |

12-1/8 |

|

BR1206307 |

13/16 |

12-1/8 |

|

BR1222307 |

7/8 |

12-1/8 |

|

BR1238307 |

15/16 |

12-1/8 |

|

BR1254307 |

1 |

12-1/8 |

|

BR1020330 |

2.0 |

330 |

|

BR1025330 |

2.5 |

330 |

|

BR1030330 |

3.0 |

330 |

|

BR1035330 |

3.5 |

330 |

|

BR1040330 |

4.0 |

330 |

|

BR1045330 |

4.5 |

330 |

|

BR1050330 |

5.0 |

330 |

|

BR1060330 |

6.0 |

330 |

|

BR1065330 |

6.5 |

330 |

|

BR1070330 |

7.0 |

330 |

|

BR1075330 |

7.5 |

330 |

|

BR1080330 |

8.0 |

330 |

|

BR1085330 |

8.5 |

330 |

|

BR1090330 |

9.0 |

330 |

|

BR1095330 |

9.5 |

330 |

|

BR1100330 |

10.0 |

330 |

|

BR1105330 |

10.5 |

330 |

|

BR1110330 |

11.0 |

330 |

|

BR1115330 |

11.5 |

330 |

|

BR1120330 |

12.0 |

330 |

|

BR1125330 |

12.5 |

330 |

|

BR1130330 |

13.0 |

330 |

|

BR1135330 |

13.5 |

330 |

|

BR1140330 |

14.0 |

330 |

|

BR1145330 |

14.5 |

330 |

|

BR1150330 |

15.0 |

330 |

|

BR1155330 |

15.5 |

330 |

|

BR1160330 |

16.0 |

330 |

|

BR1165330 |

16.5 |

330 |

|

BR1170330 |

17.0 |

330 |

|

BR1175330 |

17.5 |

330 |

|

BR1180330 |

18.0 |

330 |

|

BR1185330 |

18.5 |

330 |

|

BR1190330 |

19.0 |

330 |

|

BR1195330 |

19.5 |

330 |

|

BR1200330 |

20.0 |

330 |

|

BR1205330 |

20.5 |

330 |

|

BR1210330 |

21.0 |

330 |

|

BR1215330 |

21.5 |

330 |

|

BR1220330 |

22.0 |

330 |

|

BR1225330 |

22.5 |

330 |

|

BR1230330 |

23.0 |

330 |

|

BR1235330 |

23.5 |

330 |

|

BR1240330 |

24.0 |

330 |

|

BR1245330 |

24.5 |

330 |

|

BR1250330 |

25.0 |

330 |

|

BR1255330 |

25.5 |

330 |

|

BR1260330 |

26.0 |

330 |

|

BR1265330 |

26.5 |

330 |

|

BR1270330 |

27.0 |

330 |

|

BR1275330 |

27.5 |

330 |

|

BR1280330 |

28.0 |

330 |

|

BR1285330 |

28.5 |

330 |

|

BR1290330 |

29.0 |

330 |

|

BR1300330 |

30.0 |

330 |

|

BR1305330 |

30.5 |

330 |

|

BR1310330 |

31.0 |

330 |

|

BR1315330 |

31.5 |

330 |

|

BR1320330 |

32.0 |

330 |

|

BR1325330 |

32.5 |

330 |

|

BR1330330 |

33.0 |

330 |

|

BR1335330 |

33.5 |

330 |

|

BR1340330 |

34.0 |

330 |

|

BR1345330 |

34.5 |

330 |

|

BR1350330 |

35.0 |

330 |

|

BR1355330 |

35.5 |

330 |

|

BR1360330 |

36.0 |

330 |

|

BR1365330 |

36.5 |

330 |

|

BR1370330 |

37.0 |

330 |

|

BR1375330 |

37.5 |

330 |

|

BR1380330 |

38.0 |

330 |

|

BR1385330 |

38.5 |

330 |

|

BR1390330 |

39.0 |

330 |

|

BR1400330 |

40.0 |

330 |

|

BR1405330 |

40.5 |

330 |

|

BR1410330 |

41.0 |

330 |

|

BR1415330 |

41.5 |

330 |

|

BR1420330 |

42.0 |

330 |

|

Standard |

Diameter D,mm |

|

|

Range |

Tol. |

|

|

2≤0D<3 |

+0.15~+0.30 |

|

|

3≤OD≤6 |

+0.30~+0.50 |

|

|

6 |

+0.30~+0.60 |

|

|

12 |

+0.30~+0.70 |

|

|

16 |

+0.30~+0.80 |

|

|

Length L,mm |

||

|

Range |

Tol. |

|

|

330 |

+5,-0 |

|

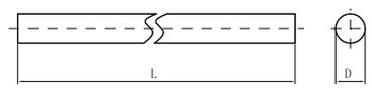

Ground Rods

Inch

|

ISO h6/h5 TYGK Production Category H2/H7 |

||

|

Specification |

Dimension |

|

|

OD |

L |

|

|

BR1063307 |

1/4 |

12-1/2 |

|

BR1071307 |

9/32 |

12-1/2 |

|

BR1075307 |

19/64 |

12-1/2 |

|

BR1079307 |

5/16 |

12-1/2 |

|

BR1083307 |

21/64 |

12-1/2 |

|

BR1087307 |

11/32 |

12-1/2 |

|

BR1091307 |

23/64 |

12-1/2 |

|

BR1095307 |

3/8 |

12-1/2 |

|

BR1099307 |

25/64 |

12-1/2 |

|

BR1103307 |

13/32 |

12-1/2 |

|

BR1107307 |

27/64 |

12-1/2 |

|

BR1111307 |

7/16 |

12-1/2 |

|

BR1115307 |

29/64 |

12-1/2 |

|

BR1119307 |

15/32 |

12-1/2 |

|

BR1123307 |

31/64 |

12-1/2 |

|

BR1127307 |

1/2 |

12-1/2 |

|

BR1134307 |

17/32 |

12-1/2 |

|

BR1142307 |

9/16 |

12-1/2 |

|

BR1158307 |

5/8 |

12-1/2 |

|

BR1174307 |

11/16 |

12-1/2 |

|

BR1190307 |

3/4 |

12-1/2 |

|

BR1206307 |

13/16 |

12-1/2 |

|

BR1222307 |

7/8 |

12-1/2 |

|

BR1238307 |

15/16 |

12-1/2 |

|

BR1254307 |

1 |

12-1/2 |

|

BR1060330 |

6 |

330 |

|

BR1070330 |

7 |

330 |

|

BR1080330 |

8 |

330 |

|

BR1090330 |

9 |

330 |

|

BR1100330 |

10 |

330 |

|

BR1110330 |

11 |

330 |

|

BR1120330 |

12 |

330 |

|

BR1130330 |

13 |

330 |

|

BR1140330 |

14 |

330 |

|

BR1150330 |

15 |

330 |

|

BR1160330 |

16 |

330 |

|

BR1170330 |

17 |

330 |

|

BR1180330 |

18 |

330 |

|

BR1190330 |

19 |

330 |

|

BR1200330 |

20 |

330 |

|

BR1210330 |

21 |

330 |

|

BR1220330 |

22 |

330 |

|

BR1230330 |

23 |

330 |

|

BR1240330 |

24 |

330 |

|

BR1250330 |

25 |

330 |

|

BR1260330 |

26 |

330 |

|

BR1270330 |

27 |

330 |

|

BR1280330 |

28 |

330 |

|

BR1290330 |

29 |

330 |

|

BR1300330 |

30 |

330 |

|

BR1310330 |

31 |

330 |

|

BR1320330 |

32 |

330 |

|

BR1330330 |

33 |

330 |

|

BR1340330 |

34 |

330 |

|

BR1350330 |

35 |

330 |

|

BR1360330 |

36 |

330 |

|

BR1370330 |

37 |

330 |

|

BR1380330 |

38 |

330 |

|

BR1390330 |

39 |

330 |

|

BR1400330 |

40 |

330 |

|

BR1410330 |

41 |

330 |

|

BR1420330 |

42 |

330 |

|

Standard |

Diameter D,mm |

|

|

Range |

Tol. |

|

|

6 |

h6,h5 |

|

|

Length Lmm |

||

|

Range |

Tol. |

|

|

330 |

+5,-0 |

|

|

Type:C B T 3 0 5 Microcomputer controlled electronic flexural testing machine Accuracy: 1N GB/T3851-1983≈ISO3327-1982 ASTM B406-1996 |

|

Type:R B 2 0 0 0 R Rockwell Hardness Tester USA Wilson GB/T3849-1983≈ISO3788/1-1982 ASTM B294-1992 |

|

Type:LD J - 5800 Magnetic performance meter Imported magnetic saturation and coercivity test all-in-one machine |

|

Electronic balance:XS105 ME TTLER TOLEDO Accuracy:0.01mg GB/T3850≈ISO3369 ASTM B294 |

|

Metallographic microscope:Image r .A2m CarlZeiss GBT3479-1983≈ISO4505-1978 ASTM B276-2005 GBT3448-1983≈ISO4499-1978 ASTM B390-1992 |

Property testing instruments

INQUIRY

Related product categories

- large diameter carbide roll rings for alloy steel rolling

- tungsten carbide rolls for hot rolling

- long-life roller rings for mance rolls

- tungsten carbide rolls for mance rolls

- custom-manufactured roll rings for bar mills

- carbide roll rings for plate mills

- carbides rolls for wire milling for mold making

- tungsten carbide rolls Japan

- high-quality carbide roll rings Pakistan

- china cutting tool suppliers

- cnc end mill tool

- carbide mill bits

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de